WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

mine ball mill sizing explanation mine ball mill sizing explanation The process design of gold leaching and carbon-in deep underground mine. In this case, ball milling circuits, typical of older sizing Cost estimates Optimization ...

Product Speci cation - Krakatau Steel contents pt krakatau steel (persero) tbk profile company 4 flat product manufacturing overview 6 steel slab product 7 1 ... ball mill sizing in a steel plant - . ball mill sizing in a steel plant. Q: Ball ...

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill & ball mills, the ore in order to liberate the minerals. In ...

My Tech. Report on Ball mill. Cairo University Chemical Engineering Department . SlideShare Explore Search You Upload Login Signup Home Technology Education ...

The cement mill Cement clinker is usually ground using a ball mill. ... are more efficient at reducing the particle size... The Understanding Cement Newsletter. ... Ball Mill Design,Ball Mill Sizing,Design Of Ball Mill Ball Mill Design,Ball Mill ...

Warning: These calculators give a rough and initial idea for sizing a cement ball mill. To go ead, a deeper study is necessary with ball mills suppliers. Calculators, examples are opened in a new tab, infographics in a popup window!

selection chart for ball mill for cement - tutorcms Cement Ball Mill Sizing Explanation - The Cement Grinding Office. This method only gives a rough and initial idea for sizing a cement ball mill. Chat Online

The optimal ball diameter in a mill 331 In accordance with Eq. 2, the necessary condition for grain comminution is: 2 2 3 1 bo Kd. (5) So, .

You Are In: Home / PRODUCTS / understanding ball mill sizing PRODUCTS Ball Mill Belt Conveyor Bwz Heavy Duty Apron Feeder Cs Cone Crusher Flotation Machine Hammer Crusher High Frequency Screen Hj Jaw Crusher ...

Mineral Processing Plant Mineral Processing Project and dynamic separators, rotary screens, mineral grinding plant, ball mills for wet manufacturer supplier ... Rotary Dryer Manufacturers,Ball Mill Suppliers,Rotary ball mill ...

Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant Sanjeev T. Patil Department of Metallurgical and Materials Engineering, Visvesvaraya National Institute of Technology, Nagpur-440010, India. ...

We will then be able to answer such questions as whether the ball mixes used in the cement mill were optimum, what would be the effect of classifying liners which classify the balls by size along the mill length, etc_ It should 1 ...

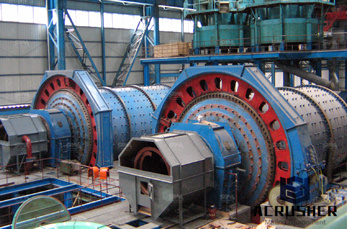

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of ...

FL ball mill for cement grinding Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or ... Ball Mill Design Calculation mayukhportfolio. Ball mil design ...

Sourcing Guide for Ball Mill Sizing: China manufacturing industries are full of strong and consistent exporters. We are here to bring together China factories that supply manufacturing systems and ...

2016/10/24· More Details : ball mill calculation xls for cement plant Empresa TMEP Copyright ? 2014-2020.ball mill calculation xls for cement plantMobile Crushing Plant. ... Ball Mill Design ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed. Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant.

Full text of "Holderbank Cement engineering book" - Internet, For grinding coal, slag, cement, etc, adaptations to mills and systems have to be made, aspects have to be considered when sizing a vertical roller mill: * grinding * drying ...

The method is used to size a cement ball mill. Efficiency correction factors are applied with the Bond equation. The method is valid both for clinker grinding and for raw materials grinding. This method only gives a rough and initial idea ...

1.1 FLS UMS Type Cement Ball Mill In 1893 FL (FLS) firm acquired the rights to a new mill type, the tube mill, from the French/Danish inventor. After being thoroughly redesigned and refined, the tube mill used the raw mill ...

Ball mill A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the ...

めまれている· How to optimize a 6 pound ball mill to safely and effectively ball mill homemade black powder. ... The ball mill jars The first thing that struck me when I first looked at these mills was the nice quality of the mill jars. These things are ...

Cement mill - Wikipedia, the free encyclopedia 5 Roller mills; 6 High-pressure roll presses; 7 Capacity of cement mills; 8 Control of ... A Ball mill is a horizontal cylinder partly filled with steel balls (or occasionally other .... The cement ...

Cement technology: Cement Ball Mill Sizing LinkedIn Nov 16, 2012 ... Cement technology: Cement Ball Mill Sizing. Marc P. Grinding Process Engineer chez The Cement Grinding Office. After the presentation of the... Crushers for ...

WhatsApp)

WhatsApp)