WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Haypi Monster derivation of critical speed of ball mill Sep 10, 2013 ... Ball mill critical speed, ball mill efficiencyWhat is the ball mill critical speed ... to improve ball mill efficiency ? ball mill critical speed calculation... critical speed ...

STUDY ON THE EFFECT OF HIGH ENERGY BALL MILLING (A NANO MATERIAL PROCESS) ON THE MICROSTRUCTURE AND MECHANICAL PROPERTIES OF A (Al-Si-Fe-Cu) ALLOY A THESIS SUBMITTED IN PARTIAL ...

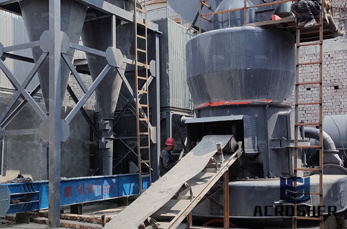

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of ...

ball milling ball speed Simulation of ball motion and energy transfer in a plaary between the vial wall and ball, acts on the samples to be milled. As the driving speed increases, the Cori- olis force (rotation bias force) forces the milling ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed. Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant.

PDF Book Library Critical Speed Of Ball Mill Summary Ebook Pdf: Critical Speed Of Ball Mill a ball mill critical speed actually ball rod ag or sag is the speed at which the centrifugal forces equal gravitational forces at the mill shells ...

Ball Milling Equipment Porcelain Jars - Internal Capacity PTA-01 Model Ball Mill Wheel Attachment Fits on the VL-Whisper or RK-Whisper with a 12" wheel-head Ball mills have been used for decades to grind and mix materials used ...

Surfactant-assisted ball milling: a novel route to novel materials with controlled nanostructure... 5 below this critical speed to keep the ball moving. Additionally, high speed yields high temperature that might contaminate the powder or ...

Do you want to show high speed ball milling or other products of your own company? Display your Products FREE now!

2015/06/19· めまれている· https:// Learn about Ball Mill Critical Speed and its effect on inner charge movements. The effect of Ball Mill RPM speed going from sub-critical to super-critical helps ...

Supercond. Sci. Technol. 11 (1998) 1153–1159. Printed in the UK PII: S0953-2048(98)93380-2 Effect of ball milling materials and methods on powder processing of Bi2223 superconductors M Yavuzy, H Maeday, L Vancez,HKLiuxand ...

Bigger size media has more crushing effect as well as smaller sizes better grinding effect. Rotation speed of the ball mill is also one of the factors changing thenbsp » Learn More effect of speed in ball milling. torque on the driving ...

ATTRITORS AND BALL MILLS HOW THEY WORK Robert E. Schilling, M. Yang UNION PROCESS INC. Akron, Ohio Presented by Robert "Bob" Schilling Presented at the Philadelphia Society For Coatings Technology Inc.

めまれている· At some point in this pyro-art adventure, we start to hear or get the feeling, that we need a ball mill to grind chemicals very fine or to make high-quality black powder. This project will not attempt to be a comprehensive review of ball ...

The 12 Principles of Green Chemistry Prevention of waste Atom Economy Less Hazardous Chemical Syntheses Design Safer Chemicals ... Types of Ball Mills Drum ball mills Jet-mills Bead-mills Horizontal rotary ball mills Vibration ball mills

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed - Critical Speed needs. ... Jar Rolling Mills ABBE Jar Rolling Mills are designed to support ...

Ball Milling ProcessIntroduction: The ball mill is the key milling machine to break and to smash materials. It also is an effective tool for many materials ground into fine powder. It is widely used in cement, silicate, ...

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input. ... RETSCH ball mills are available as mixer mills as well as planetary ball mills. ...

jaw crusher, cone crusher, impact crusher, mobile crusher,grinding . iron ore ball mill in india. ball mill design is actually widely used . ball mill circulating load ball mill critical speed calculation ball mill design programs ball .

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell's inside surface and no balls will fall from its position onto the shell. The imagery below ...

Herein, we report on the solvent-free Sonogashira reaction utilizing high speed ball milling. Sonogashira coupling of a variety of para substituted aryl halides were performed with trimethylsilylacetylene or phenylacetylene. We observed ...

"Mining equipment used in drilling, crushing or grinding of various minerals are put to the test and may require more than one rehabilitation before being turned ... What is a Ball Mill? A ball mill is a type of grinding mill, purposed ...

rotation speed, type of milling (wet or dry) as well as the size of the steel balls [3]. Mills are also one of the largest energy consumers in processing plants which can be estimated to about 50% of the total energy utilized in ...

2014/05/21· めまれている· Ball mill, Grinding machine, Wet ball mill, Dry ball mill, Milling machine, Eric Zhang Add to Want to watch this again later? Sign in to add this video to a playlist. Sign in Share More Report Need to .

WhatsApp)

WhatsApp)