WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Jiangsu ChinaMining Heavy Equipment Co.,Ltd (the former is Nantong China Mining Cement Equipment Factory) is a core enterprise of Jiangsu province of China Mining ...

In dry and semi dry processes for manufacturing of cement, the raw materials are crushed and fed in the correct proportions into a grinding mill.

Cement grinding with HoromillCosts & Benefits . Parent Process: Finish Grinding; Energy Savings Potential: Power consumption can be reduced by ...

Cement Grinding: As the last process, the cement grinding will consume a great deal of electricity. And in this process, special size granule cement will be obtained. ...

What Is the Cement Manufacturing Process? The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials ...

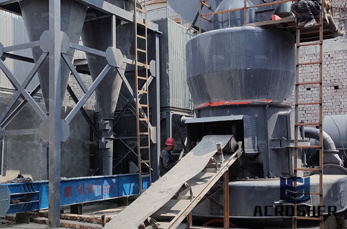

Cement production line is the production line of cement equipment consisting of a series of equipments. Mainly by crushing and pre homogenization, preparation of raw ...

Application of Intellectual Control Treatment for Cement Grinding Process LI Cong School of Electrical Engineering, University of Jinan . Jinan

The use of a good Cement clinker grinding aid can be vital in today's increasing material demands. Along with the obligation to process increasingly larger ...

Cement process machine,Cement grinding mill process,Cement. cement grinding plant and, cement clinker factory,Divided by cement production process, you will find ...

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology F.L.

The Cement Grinding Office. Our reference list. GK software new version 6 is now available with 87 calculators (4 versions 32 and 64 bits) - The general sheet gives ...

Cement grinding Vertical roller mills versus ball mills Grinding process Dehydration of the gypsum added to the cement In the grinding process heat will be .

Cement mill, cement Grinding mill for cement Grinding process in cement plant. Ball mills and vertical mills are the best choice for your cement Grinding plant.

Portland cement is the most common type of cement in general use around the world as a basic ingredient of concrete, mortar, stucco, and non-speciality grout.

Cement is the basic ingredient of construction and the most widely used construction material. Its manufacturing includes extraction, proportioning, grinding,

CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Minerals Process Technology Asia-Pacific, Brisbane, Australia e-mail: alex.jankovic@

Improved Cement Quality and Grinding Efficiency ... Grinding of clinker is the last and most energy-consuming stage of the cement manufacturing process, ...

2011-5-9 · Slag Cement Prepared by Separate Grinding Process Jin Zhigang (Shandong Province Building Materials Industrial Design and Research Institute, Jinan 250022 ...

Cement Grinding Plants. Flyer PDF » Contact Us » When raw materials availability, funding, schedule or other factors do not support the implementation of a full ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ...

Cement Grinding Process, Wholesale Various High Quality Cement Grinding Process Products from Global Cement Grinding Process Suppliers and Cement Grinding Process ...

Cement manufacturing - brief description of a cement mill. Cement clinker ... Clinker grinding uses a lot of energy and the cement ... of a complex process like ...

11.6 Portland Cement Manufacturing 11.6.1 Process Description1-7 Portland cement is a fine powder, gray or white in color, that consists of a mixture of

China Cement Grinding Process, China Cement Grinding Process Suppliers and Manufacturers Directory - Source a Large Selection of Cement Grinding Process .

WhatsApp)

WhatsApp)