WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

The Emax is an entirely new type of ball mill for high energy ... The high energy input is a result of an unrivaled speed of 2000 min-1 and the optimized jar design.

How to Size a Ball Mill -Design Calculator & Formula. ... E is the specific energy required for the grind, ... Ball milling – a ball mill with a diameter of 2.44 ...

costs (energy and wear). ... A direct measurement of the ball level in the mill, more ... Mill speed Soft design Aggressive design

A cement mill (or finish mill in ... of grinding in a ball mill is much greater than ... the material than in a ball mill, and is therefore more efficient. Energy ...

Synthesis of Nanomaterials by High Energy Ball ... high-energy ball milling is a way of modifying the conditions in which ... The ball mill system consists ...

Browser Tool for Ball Mill Design - Energy Required for Comminution

Cement grinding Vertical roller mills versus ball ... of a mill design that has ... with the mill optimised with a view to low energy consumption ...

Choosing a SAG Mill To Achieve Design Performance ... SAG mill, design, ... that represents the energy required to grind the ore represented by that sample at optimum ...

Understanding Ball Mill Sizing. ... Crystal Growth & Design; E; Energy & Fuels; ... Industrial & Engineering Chemistry Process Design and Development. Stewart ...

High Energy Ball Mill E High Energy Ball Mill max Faster and finer grinding than with any other ball mill ... design which improves mixing of the sample

2 MODELLING THE SPECIFIC GRINDING ENERGY AND BALL-MILL SCALEUP Ball-mill scale up (Bond's Law) Data: zBond work index w i .

transfer of kinetic energy of the moving grinding media ... The design of a ball mill can vary significantly depending on the size of the required mill, the

Ball Mill. 140 likes. ... It determines the mineral processing design and equipment ... Wet energy saving ball mill. Energy-saving Ball from the feeding ...

Ball Milling Design [ 4.6 - 6784 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the ... Planetary Ball Mill, High Energy Ball ...

design of the new high energy ball mill E max allows for produc - ... High energy ball mills and planetary ball mills provide the required kinetic energy for

Mar 31, 2008· I need to design a l end discharge ball (tube) mill for grinding kaolin as my engineering design project. where can I find necessory steps to follow the ...

ATTRITORS AND BALL MILLS HOW THEY WORK Robert E. Schilling, ... surface energy of the ... The critical speed of a ball mill is calculated as 54.19 divided by the ...

The Selection and Design of Mill Liners . ... energy transfer, ... High–low double wave ball mill liners – These are a refinement of the wave liner, ...

Grinding in Ball Mills: Modeling and Process Control ... The design of a ball mill can vary significantly ... of the mill shaft power and the energy consumed in the ...

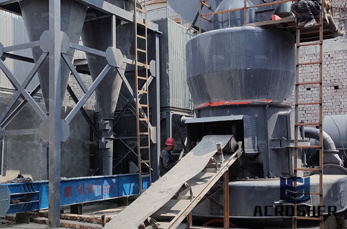

Energy Saving Ball Mill. Cylindrical energy saving grid ball mill design consist of feeding part, discharging part, rotary part, transmission part (reducer, small ...

Video embedded· Make a Ball Mill in 5 ... Wiki says "A ball mill is a type of grinder used to ... how to make a ball mill with lego and a pvc pipe --includes digital design .

Notes on Ball Mill Design - Energy Required for Comminution. Feed material is assumed coarse hard rock. Feed Size and Product Size are 80% passing mesh sizes (micron)

Structure_Energy Saving Ball Mill. Click Image to Zoom. Cylindrical energy saving grid ball mill design consist of feeding part, discharging part, rotary part, ...

A vertical ball mill as a new reactor design for biomass hydrolysis and ... A vertical ball mill ... of biomass from rice industry as a source of renewable energy.

WhatsApp)

WhatsApp)