WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Clinker produced by early static kilns was in the form of large pumice-like lumps. Rotary kiln clinker on the other hand, because of the rolling action of the kiln, emerges as fairly regular roughly spherical hard nodules of diameter ...

The experience encompasses complete plant design including limestone crushing and screening, calcining (of both high calcium and dolomitic limestones), kiln firing, emissions, product handling and storage, and lime ...

Construction Period 14 Months (April 1995 - June 1996) Project Description Design, construction, manufacturing and complete mechanical and electrical erection of kiln precalcination unit. Main Contractor GAMA Industry Inc. Scope ...

gypsum vertical shaft kiln - fsi [DOC] Cement Kilns firing Hazardous Waste - Stockholm · Web viewIn China most cement is produced in vertical shaft kilns, This clinker is then ground together with ... » Learn More rotary kiln ...

Screw Conveyors - Continental Conveyor design and manufacture of bulk material handling equipment and is thereby your assurance, Continental screw conveyors and components are designed and built in accordance with the ...

Modern lime kiln technology 1 Participants at the workshop 2 Kiln construction At the invitation of the Dannenfels-based Schwab , more than 50 experts from the lime industry met at the headquarters of the M-Group in ...

Early rotary kilns Kilns Home Early kilns Rotary kilns Coolers Firing systems Exhaust gas handling Kiln suppliers Design features of rotary kilns Wet and semi-wet process kilns Dry and semi-dry process kilns Precalciner kilns ...

gypsum vertical shaft kiln - fsi [DOC] Cement Kilns firing Hazardous Waste - Stockholm · Web viewIn China most cement is produced in vertical shaft kilns ... rotary kiln gypsum for sale - bncollegepatna gypsum shaft kiln ...

Cement Kiln Co-Processing (High Temperature Treatment) Page 1 of 11 Pesticides Treatment Technology Fact Sheet John Vijgen, International HCH and Pesticides Assoc iation and Dr.Ir. Ron McDowall, Auckland New Zealan d for ...

rotary kiln design handbook – 6 Jan 2014 . rotary kiln design handbook crushing process from XSM. Shanghai XSM ( rotary kiln design handbook crushing ... rotary kiln design handbook – Vanguard Q&A 15 Feb 2013 . steps on ...

Gypsum Calcination Rotary Kiln Plant_Calcined Gypsum rotary Gypsum Calcination Rotary Kiln Plant_Calcined gypsum rotary kiln,US $ 100,000 - 1,000,000 / Set, New, Magic Separator, Henan, China (Mainland).Source from Henan

As the gypsum industry knows, changes in a material's moisture content will influence manufacturing in many different ways. For example, a reduction in moisture can greatly impact material handling or prepare gypsum for ...

Hot Selling Design Sulfur Gypsum Activated Carbon Rotary Kiln, Find Complete Details about Hot Selling Design Sulfur Gypsum Activated Carbon Rotary Kiln,Activated Carbon Rotary Kiln,Gypsum Block Production Line ...

We design our rotary kilns to suit the needs of your process and material, from testing to finished product. Know More Hongke Heavy Machinery Large Lime Rotary Kiln Production And Export Base Know More HONGKE IS TO ...

INTRO Contents About FEECO 1 Intro to Rotary Kilns 3 ROTARY KILN OPERATION & PROCESSING How Rotary Kilns Work 5 Rotary Kiln Processes 8 SIZING & DESIGN Rotary Kiln Sizing & Design 11 Increasing Efficiency ...

The primary role of a gypsum handling system is to transfer material safely and efficiently from one location to another. While this functionality is universal regardless of industry, the equipment is not considered to be all-purpose, one ...

Pneumatic Conveying for the Cement and Gypsum Industries Schenck Process Group – Your Partner Worldwide Acting locally to support your needs the Schenck Process Group is working where you are. ...

industry » Plaster industry » Grinding and drying, gypsum calcination Grinding and drying, gypsum calcination The perfect dedusting solutions to fulfil the strictest of requirements Whether the process involves grinding, drying or ...

2015/03/13· Erisim Makina dik Fırın.... Vertical kiln Вертикальной печи. 400 ton /day Erisim Makina Alçı için ürettiği dik fırını bitirdi kurulmak üzere Yükledi ...yola çıktı.

by the handling and storage of intermediate and final materials, and by the operation of kiln systems, clinker coolers, and mills. Several types of kilns are currently used in cement manufacturing (preheater– precalciner (PHP ...

334 Cement Manufacturing levels by reducing the mass load emitted from the stacks, from fugitive emissions, and from other sources. Collection and recycling of dust in kiln gases is required to improve the efficiency of the operation ...

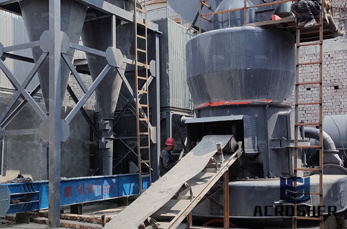

Product Description Gypsum rotary kiln is an industrial equipment, which can make a lot of production. And the production of gypsum has a great role, mainly used for construction of building engineering, pharmacological treatment ...

Pneumatic Conveying Solutions for the Cement and Gypsum Industries Overview: Clyde Process provides low energy, low maintenance and environmentally enhanced material handling solutions for customers who operate in the ...

• Solid design Higher kiln capacities and new grinding processes in the cement industry require Bucket Elevators with high conveying capacities and center distances. AUMUND Double Bucket Elevators type BWZ-D are theplants. ...

WhatsApp)

WhatsApp)