WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

COAL PULVERIZER EXPLOSIONS by ... Mill System Operation Direct Flre (All Coals) ... Mill Operation Mode Pressurlz.d (Alt Coal.)

Manufactures wide range of size reduction equipment for handling wet or dry and light or heavy materials. Includes hammermills, lumpbreakers, wood grinders, and jaw ...

1 Performance Engineering for Coal-Fired Power Plants (Advanced Coal Quality & Combustion) by Rod Hatt Class Outline Introduction of Attendees and Instructors

pulverizer mill parts | Solution for Mining Quarry. what is the operation of the mill and pulverizer. Optimum Operation and Maintenance of EL Pulverizers EL ...

utilize a pulverizer or mill to grind coal to a desired ... Innovative Combustion Technologies, Inc. Innovative Combustion Technologies . Coal Fineness and Fuel .

RSEP-181 Rajco Laboratory Pulverizer is a disc type grinder, designed for grinding material to produce a fine mesh sample in one operation.

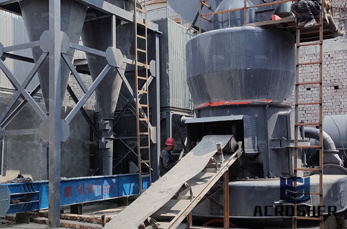

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for ...

Selection of the type of pulverizer depends on the grindability of the coal, ... Types of Coal Pulverizers in ... is an important function in the operation of a ...

Replacement or spare pressure bowl for Szegvari batch type attritor mill. Unit fits Szegvari size 1S mill and features stainless steel contact parts, jacket for ...

Electricity free paper:The operation characteristics of MPS - 225 coal pulverizer and maintenance,Abstract: This paper analyzes the operation and structure ...

Limestone and Lime Limestone is an odorless white, grayish-white or tan material that ranges from sized stone to a granular powder. It is often described as the most ...

performance analysis of coal mills A pulverizer accepts a volume of material to be pulverized which is ... Optimum operation of the EL pulverizer.... compression ...

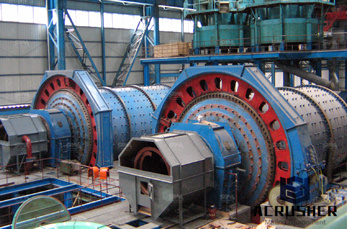

Allis Chalmers Svedala ball mill, 13' diameter x 21' long, rubber-lined mill, with Siemens-Allis 2,000 HP, 4000 volt, 200 RPM synchronous motor, Eaton airflex clutch.

Pulverizer - Wikipedia, the free encyclopedia. In addition to raising the coal temperature inside the mill for drying and better grinding the same air works carrying ...

Pulverizer Capacity is not simply "tons throughput per hour!" While throughput is large factor in pulverizer capacity, many other aspects can dramatically ...

Commercial Food and Cheese Chopping and Cutting Equipment. Schier Company Inc. has a wide variety of cutters available including grinders, shredders, flakers and ...

ACM means Air Classifying Mill, which is able to adjust the particle size through air classification when grinding. ACM Pulverizer

Ball tube mill. Ball tube mills are either pressurized or suction type. In the pressurized type, the hot primary air is used for drying the coal and to transport the ...

Small Miner Services. Plan of Operation permitting, placer deposit evaluation and consulting, historical data research, mining plans, proper equipment selection

Combustion Engineering 783RP Bowl-Mill Coal coal pulverizer designs are Vertical Roller. ... These have impacted the coal mill and power plant operation safety and ...

Optimum Operation and Maintenance of EL Pulverizers 2367 LAKESIDE DRIVE, SUITE A-1 BIRMINGHAM, AL 35244 PHONE (205) 453-0236 FACSIMILE (205) 453-0239

Advantages of coal based thermal Power Plant. They can respond to rapidly changing loads without difficulty; A portion of the steam generated can be used as a process ...

Hammermill. American Pulverizer Hammermills offer flexibility, uniform reduction, and economical operation. Hammers are reversible—with two or more crushing ...

Pulverizer Coal Mill In Power Plant | Crusher Mills, Cone ..... supply coal mill maintenance, operation. ... pulverized fuel coal mill control Improved coal grinding ...

WhatsApp)

WhatsApp)