WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

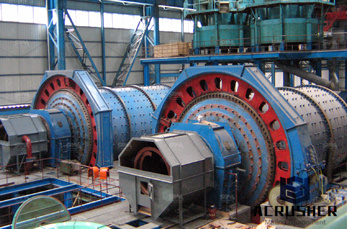

A cement mill (or finish mill in ... Ball mills are normally operated at around 75% of critical speed, so a mill with diameter 5 metres will turn at around 14 rpm.

A cement mill (or finish mill in ... Ball mills are normally operated at around 75% of critical speed, so a mill ... The efficiency of the early stages of grinding in ...

Critical rotation speed of dry ball-mill was studied by experiments and by numerical simulation using Discrete Element Method (DEM). The results carried out by both ...

Critical speed of ball mill - SBM - unisbm. Ball mill is the most common used grinding mill for stone powder making plant or mineral ore processing plant.

formula for critical speed ball mill. Nowadays, the XSM stone crusher(formula for critical speed ball mill) in European style undoubtedly becomes the most welcome ...

This page is about critical speed of a ball mill, click here to get more infomation about critical speed of a ball mill.

Jiangxi Ball mill in the outer ball just with the tube together with the rotation of the ball when the ball is not falling speed, said the critical speed, with NC ...

The Critical Speed is used for the determination of ball mill ideal operating speed. But for comparison, rod mills would operate between 50% to 95% of the critical speed.

S.O. - Super Orion Ball Mill - hosokawa-alpine Ball mills are usually operated at 75% of the critical speed. The critical speed is the speed where, mathematically ...

critical speed in ball mill. Crushing Equipment. Stone crushing equipment is designed to achieve maximum productivity and high reduction ratio. Grinding Equipment.

The point where the mill becomes a centrifuge is called the "Critical Speed", and ball mills usually operate at 65% to 75% of the critical speed. Ball Mills are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns.

The critical speed of a ball mill is calculated as 54.19 divided by the square root of the radius in feet.

SAGMILLING.COM .:. Mill Critical Speed Determination. The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal ...

Mill Critical Speed Determination. The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces ...

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, ... The grinding works on the principle of critical speed.

show the critical speed of ball mill mathematical. Jan 22, 2016 A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at You'll find a good on-line ...

How can you design of ball mill - Answers. What is a ball mill and how does it function? Ball Mill is widely used in metal and nonmetal mines, building materials and ...

Emergency services are available for those critical down times when you must get back and running. ASAP Our company has been performing quality work for .

critical speed formula for ball mill_Rod mills, how they function Mine Rod mills are very similar to ball mills, except they use long rods for grinding media The rods ...

Mill Speed - Critical Speed. Mill Speed. No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar rolling mill, its rotational speed is important to proper and efficient mill operation. Too low a speed and little energy is imparted on the product.

Grinding & Classification Circuits. ... If the case is a little reduces the critical speed to increase the ball mill level, ...

The critical speed of ball mill is given by, where R = radius of ball mill; r = radius of ball. For R = 1000 mm and r = 50 mm, n c = 30.7 rpm.

moran: Control the Rotation Speed of Ball Mill Apr 25, 2013 ... The ball mill rotating speed is called critical speed when the outmost ... to calculated, and now only ...

Critical Speed of Ball Mill For a ball mill, it does not have a constant critical speed, because of the centrifugalization of the steel balls is different accor

WhatsApp)

WhatsApp)