WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

ARE SAG MILLS LOSING MARKET CONFIDENCE ... including a high level discussion on capital and operating costs ... Different combinations of SAG mill ball charge and ...

Optimisation of the secondary ball mill using an on-line ... as well as energy and media costs ... to correlate the ball load compactness with the mill operating and ...

Processing of Magnetite Iron Ores – Comparing Grinding ... minimise operating costs, ... consisting of an AG mill followed by cobber magnetic

Ball mill working principle,Ball Mill for beneficiation product line the existing ball mill starting mode and the control mode is not saving, though so the ball mill ...

Fine Grinding as Enabling Technology ... Grinding Power to produce various product sizes in a Ball Mill ... It also eliminates the extra capital and operating ...

1 Population balance model approach to ball mill optimization in iron ore grinding Patricia M. C. Faria1,2, Luís Marcelo Tavares2 and Raj K. Rajamani3

excessive operating costs. ... For ball mills in the cement industry, ... ball mill drives deliver high energy efficiency and provide the

Ball Mill Low Operating Costs. low cost ball mill in india. roller mill,roller milling suppliers,vertical roller mill,roller mill low operating cost. hour ball ...

grinding mills. Grinding mills ... quality of the operating mill. They ... reduced mineral processing costs and increased throughput tonnages, there

The high energy efficiency of stirred mills compared to ball mills is ... influence on mill parameters such as energy efficiency, internal wear and operating costs.

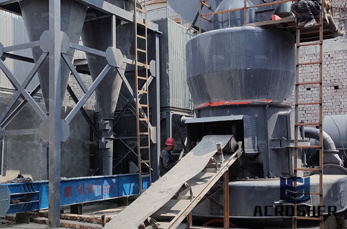

capital and operating cost of ball mill for bauxite . Mine ore grinding mill used for mineral mining, processing plant Mine ore grinding mill is used for mineral ...

The Bond Ball Mill Grindability Test is probably based on a laboratory grindability test first described by Maxson, ... operating costs of the test cheaper.

Stirred Milling 3 The Stirred Media Detritor (SMD) is a fluidized, vertical stirred mill designed for optimum grinding efficiency for fine and

ball mill manufacturing machines : Ball mill - Wikipedia, the free encyclopedia. The ball mill is a key piece of equipment for grinding crushed materials, and it is ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ...

Roller Mill Mobile Crusher Operating Cost. Roller Mill Cost Of Cone Crusher 200tph ... Comparing Two Bearing Operating Costs of Ball Mill ...

Ball Mill Low operating costs Stone Crusher Machine The design of this series was geared to optimized production, operating and maintenance costs. READ MORE.

and plant capital and operating costs. In the past 60 years, ... rod and/or ball-mill circuits. ... Secondary crushing: worth the cost?

Ball mill - Wikipedia, the free encyclopedia. A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing ...

Calculation of the power draw of dry multi-compartment ball mills 225 The mill load that is the volume of charge in the mill is the principal determinant of

of processed mineral or the minimizing of operating costs due to ... EGL 9,000 kW ball mill operating in East Africa. In grinding, a wet process is most commonly ...

Grinding Cost Analysis. ... accounted for 30% in overall mineral operating costs, ... production integration,it covers about 50% of the area of the ball mill system;

Ballmill Operational Parameters; ... ball mill operating parameters of ball mill ... The Zenith Mining Machine is custom designed to reduce your operating costs ...

TY - CHAP. T1 - Population balance model approach to ball mill optimization in iron ore grinding. AU - Faria,Patricia M C. AU - Tavares,Luís Marcelo

WhatsApp)

WhatsApp)