WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

... impact on specific power consumption and ... liner type, ball gradation and percent filling degree. ... of changing mill filling degree with respect ...

Optimization of mill performance by using. J o u r n a l P a p e r Introduction The performance of tumbling mills is sensitive to the volumetric mill filling which ...

ball mill filling degree formula for charging of grinding media in cement plant. Description : The grinding charge of rotary mills – Analele Universitatii Dunarea ...

ball mill filling degree calculation - MTM Crusher. determine cement mill volume. Please fill in your name and your message and do not forget mail and/or phone if ...

Ball filling and mill fractional speed were kept constant respectively at 20% and 60% while slurry filling was varied ... And for the same filling degree of slurry, ...

ball mill for fat filling degree. News | Anson Mills – Artisan Mill Goods. Fall Behind. Summer stole a month from autumn this year, giving those of us in the ...

The measurement of the ball charge volume load (or filling degree) is essential to maintain the absorbed power of the mill and consequently the mill production.

Thus, during calculating the grinding balls mass in ball mill (after measuring the mill filling degree with grinding media) needs to use the grinding balls bulk ...

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL PERFORMANCE Niyoshaka Nistlaba Stanley Lameck A dissertation submitted to the Faculty of Engineering and .

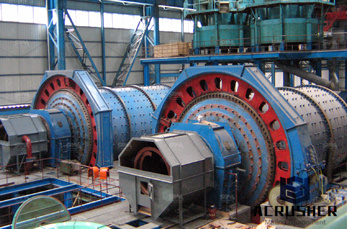

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Ball Milling - University of Massachusetts Boston. What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder.

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction needs.

Planetary Ball Mill PM 100-RETSCH-highest fineness. Planetary Ball Mills are used wherever the highest degree of fineness is required. Powerful and quick grinding ...

ball mill filling degree calculation; ras al khaima filling stone crushers; foundry for stone crusher in the philippines; mobile crusher spare parts; mesin bekas ...

Ball Mill Loading - Dry Milling. Ball Mill Loading (dry milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar ...

times more than the Ab value to produce the same degree of particle breakage. ... if the material has rod and ball mill laboratory work indices as

Optimisation of the secondary ball mill using an on-line ball and ... At constant ball filling degree, this mill's performance increases as the pool angle and dry ...

Ball Milling in Organic Synthesis: Solutions and Challanges ... Type of ball mill: ... Filling degree – Scale of ...

ball mill filling degree formula dried base conversion formula of coal. Ball Mill Motor/Power Sizing Calculation Mineral Processin, the Total Charge Filling Level to ...

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL ... The process diagnostic study for ball mill ... Chambers I & II calculated as equivalent to degree of filling of ...

2011-3-10 · How Can I calculate new ball size and weight desing for ball mill. Dear All Expert, Our ball mill has got two compartments. But soon we will building roller press ...

Sensomag®, filling sensors. Accurate measurement of ball filling degree, pulp position and pulp density influence, is of prime importance for recovery maximization ...

Ball mill ball charge degree of ball filling calculation. Scribd. Explore. EXPLORE BY INTERESTS. Career & Money. Business Biography & History; Entrepreneurship;

Internal diameter Internal length Filling degree Spec. media weight Mill speed Drive efficiency mech. Drive efficiency electr. Mill throughput Fineness product ...

WhatsApp)

WhatsApp)