WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for ...

Raw coal Inlet268 Кб. Some examples dealing with modeling of coal mills are (Rees and Fan 2003), (Zhang et al.1. An illustration of the principals of the coal mill.

Early CFD modelling work on coal combustion in the ... heat and dry the raw brown coal in the mill. ... The other two mills are switched off and only cooling air

Coal moisture-1 PFO - VBN - Aalborg Universitet,Estimation of Moisture Content in Coal in Coal Mills. Odgaard plant is the moisture content of the raw coal.

manufacturers of coal mills. manufacturers of coal mills XSM excellent mining crushing machinery products or production line design, the company is committed to ...

vertical spindle e type coal mills. vertical spindle e type coal mills XSM excellent mining crushing machinery products or production line design, the company is ...

A new model-based approach for power plant Tube-ball mill ... Once the raw coal flows into the mill ... Modelling of vertical spindle mills in coal fired ...

Raw Mills. Coal Mills. Cement Mills. Power ... Large LOESCHE coal grinding plants can be realised with ease using system components that have been employed for ...

The raw coal enters the mill via an airtight ... an ATOX coal mill based on the Hardgrove ... in large-size mills. Atox coal mill sizing

Ball Mills Coal Mill In Power Plant. ... The raw coal is then pulverized ... » modelling of vertical spindle mills in coal fired power plants » coal fired ...

Loesche-Mills for solid fuels 09060_Feste Brennstoffe_RZ_09_12dd 1 17.09.12 11:12. ... emphasis being on coal. 1927 First Loesche coal mill delivered for the

The raw coal is -Air ... The broad aim of this project was to improve / upgrade the existing coal mills ... coal mill classifier design. Coal Mill ...

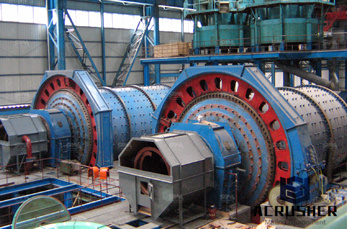

Raw Coal Mills Modelling. ... Coal mills are used to grind and dry the raw coal containing moisture and to transport the pulverized coal air mixture to the boiler.

H0w T0 Calculate Crushing Ratios Of Coal; Raw Coal Mills Modelling; Ppt On Coal Washing Methods; ... The large CE-Raymond coal mills that I worked on were .

Coke Production For Blast Furnace Ironmaking By ... A world class blast furnace operation demands the highest quality of raw materials, ... The coal-to-coke ...

Mills pulverise and dry the raw hard-coal. The raw flue gas contains, ... Status of ClaRaCCS: Modelling and Simulation of Coal-Fired Power Plants with CO2 Capture

ATOX coal mill. Working principles The raw coal enters the mill via an feed ... In the case of larger mills, changing of roller and table segments is easily

ESTIMATION OF MOISTURE CONTENT IN COAL IN COAL MILLS Peter Fogh ... coal mill. The raw coal is pulverized by the rollers and the grinding table, the pulver ized coal ...

Physical modelling for coal and saw dust combustion in a ... different raw materials, different ... The effect of fuel feed rates from the three coal mills should be ...

Modeling and Simulation of MPS Medium Speed Coal Mills: ZENG Deliang 1, GAO Shan 2, HU Yong 2: 1. Beijing Key Laboratory of Measurement and Control New Technology .

Raw Coal Bunker To Boiler Furnace Raw Coal Feeder Exhauster Hot Air Motor ... Ball-Race Mills comprise the majority of coal pulverizers currently in service at power

Part 2. Control Chapter 3 Modelling and control of pulverised fuel coal mills N.W. Rees and G.Q. Fan 3.1 Introduction There can be no doubt that the ideas of ...

Application of CDF modelling to mill classifier design Report No. COAL R240 DTI/Pub URN 04/700 March 2004

raw coal mills modelling - hkvac. . Development of a Tubeball Coal Mill Mathematical The speed of the mill barrel is 15 RPM being 75 of the critical speed.

WhatsApp)

WhatsApp)