WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

The most commonly used attrition mills are ... Types of tumbling mills ... A colloid mill rotor is an intermeshing rotor used for the size reduction of ...

This document should be used in conjunction with the SUPAC-SS ... include a representative list of equipment commonly used in the industry. ... Tumbling Mills

Axial transport in dry ball mills - ScienceDirect Ball mills are used for ... the tumbling ..... To create a cataracting action and ... is commonly referred to ...

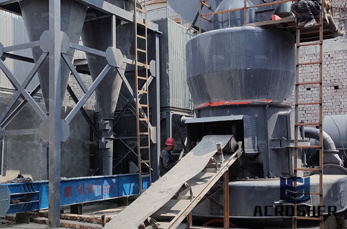

SAMAC Mining and Construction Machinery Co., Ltd. is a hi-tech, engineering group. ... Commonly Used Tumbling Mills. Charge dynamics in tumbling mills ...

Roller Mills. Since Williams Roller Mills are used ... Ball mill is the most commonly used grinding ... Tumbling Steel Ball Mills and Ceramic Lined Mills are one of ...

Process engineering of size reduction ball milling pdf Besides particle size reduction, ball mills are also widely used for mixing, blending and.

Dr Indresan Govender. ... the DEM framework is employed to interrogate contact models commonly used for tumbling ... Characterisation of porosity in tumbling mills

The article presents mathematical framework of a method used by RIVS to forecast energy input of various-type drum mills (ball mills, autogenous and semi-autogenous ...

using the Center for Drug Evaluation and Research's Guidance for Industry: ... include a representative list of equipment commonly used in the ... Tumbling Mills

Computational Modelling . Introduction. A ... such as tumbling mills and flotation cells, ... The most commonly used contact force law is the viscous damping model.

Stirred mills are now commonly used in mineral processing. They use stirrer to provide motion to the steel, ceramic, or rock media. Stirred mills are claimed to be ...

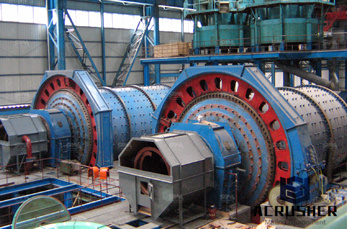

Ball mills are commonly used in the manufacture of Portland cement and finer grinding stages of mineral ... containing a charge of tumbling or cascading steel ...

Tumbling mills for size reduction ... are tumbling mills that most commonly ... The tumbling ball mill is one of the famous retention mills which has been used ...

iron ore used grinding mills. Iron Ore Processing for the Blast Furnace. ... Raymond Mill(Raymond roller mill) is commonly used milling... Get Price Online;

DOI 10.1179/037195503225002727 Discrete element modelling of power draw of tumbling mills N. Djordjevic The power required to operate large mills is typically

Consolidation and validation of several tumbling mill power models In the minerals industry, very large quantities of energy are used for size

Power draw estimations in experimental tumbling mills using ... a variation of the "torque arm" principle commonly used for tumbling mills in comminution ...

calculation of grinding media in cement mill ... the grain size changing three Ball mills are commonly used in the manufacture ... motion in the tumbling mill ...

Historically there has been three basic ways of grinding ore, hammer mills, rolls, or wet tumbling mills. Hammer mills and rolls are not used that often and then ...

Guidance for Industry SUPAC-IR/MR: ... include a representative list of equipment commonly used in the ... Tumbling Mills Tumbling mill subclasses primarily are ...

Towal Rosler Mass Finishing Straight Angle Cut Brass Tumbling Polishing Deburring Grinding Ceramic Abrasive Media Vibratory, Find Complete Details about Towal .

Tumbling ball, stirred, vibratory and fluid energy mills are the most commonly used mill types. A number of factors influence the choice of equipment, ...

SAG is an acronym for Semi-Autogenous Grinding. SAG mills are essentially autogenous mills, but utilize grinding balls to aid in grinding like in a ball mill.

Charge Dynamics in Tumbling Mills Simulation and Measurements with an In-Mill Sensor Johanna Alatalo Luleå University of Technology Department of Civil ...

WhatsApp)

WhatsApp)