WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

petroleum coke grinding mill Pneumatic mill for petcoke grinding Ř 3.4 x 7 m. ... Calcium Oxide (Burnt Lime), Gypsum, etc. VRM ... be heated for drying and grinding of the material at once. » Learn More petcoke grinding mill Petcoke ...

Control loop for cement mill VRM Hi all Can you please share with me the logic control of VRM. What factor should be included in the PID control loop? at the moment, I am using mill dP, main drive kw, recirculation. Thanks Tam

Control System Architecture for a Cement Mill Based on Fuzzy Logic The paper presents how a fuzzy controller for a cement mill is designed The classical closed loop control presents a long time until stable operation and slow Get ...

b y L O E S C H E G m b H Loesche India Round Table 2012 7 Performance – Control Loop Clinker Grinding: 1.Recirculation Damper Position = f (Mill Inlet Pressure). 2.Feed Rate = f (Mill Differential Pressure). 3.Booster Fan ...

2017/08/21· cm2/g: 4000 Cement (OPC) Slag .VRM versus BALL MILL for CEMENT GRINDING Blaine Surface. Grinding systems comparison Power Consumption when grinding to 3800 cm2/gm for 150 tph capacity . Operational Guidelines for ...

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL OPTIMISATION - CASE STUDY V.K. Batra*, D. Bhaskara Rao** and Raju Goyal*** Holtec Consulting Private Ltd., New Delhi ABSTRACT Grinding technology has been ...

How to control vertical roller mill temperature in cement ... REVIEW: vertical roller mill is the basic working principle of the disc and the roller compacted ... cone mill for grinding with temperature control - YouTube 14 Jan 2014 ...

Why use advanced process control? 2 Advanced process control from FL ensures that cement plants perform better, resulting in increased stability and higher profitability. Direct Benefits • Up to 8% higher production • Up to 6% lower ...

Advanced process control for the cement industry - Vertical Roller Mill Application. Page 10 .... change in one of the PID loops causes disturbance in the other PID loop. The two PID loops are consequently often. Read more

Process Diagonistics Studies for Cement Mill Optimization - Holtec The paper also describes the principle of the mill load control system ... Roller press in semi finish and finish grinding mode ... Ring roller mill or Horo mill.

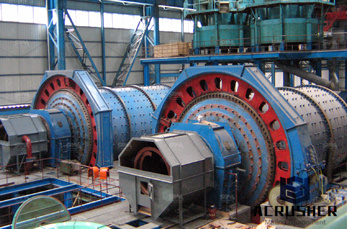

Find Out More - Digital Control Lab - AG, SAG, Ball Mill. Ball Mill Electronic Vibration measuring systems for control, fill level and process optimization in Mining and Cement. can be used to run the mill under automated loop ...

A ball mill or vertical roller mill (VRM) are used for a grinding process. performance analysis of coal mills This standardization enables selection of an appropriate mill for a specific duty. Ball... 25% to 30% of cylinder volume is ...

Control loop for cement mill VRM Hi all Can you please share with me the logic control of VRM. What factor should be included in the PID control l... Page 1 of 3 1 2 3 reg reg Subscription Subscribe to £ 195 / US$ 315 / EUR 260 ...

Grinding Pressure Of Vrm Crusher Eport - Mining Machinery ... VSI Crusher Grinding Mill MTW Series Trapezium Mill MTM Medium Speed Mill High Pressure Suspension Mill SCM Super micro Mill MXB Coarse Powder Mill Ball ...

automation in cement industry for crushing and grinding MNC AUTOMATION-Cement Plants, Cement Automation, Cement Automation ... We are equipped to undertake ... cascade control loop rotary kiln? AC drive with PID control ...

Training Courses based on the Grinding Software Presentations available The Cement Grinding Office 2015 - Presented by Marc Piccinin Grinding Software list of calculators Section 1: Ball Charges Kit 1. Ball charges2. BallMills ...

vrm cement mill suppliers-artificial sand making machine tamilnadu,double head motor bench grinding machine,mineral iron ore daily price in malaysia,portable rock crusher capacity in canada,cone crusher supplier in the philippines

re VRM vs Ball Mill for Cement Grinding Specific power consumption- high for ball mill and Low for VRM Maintenance costs- high for VRM and low for Ball mill Process control/process technology- ball is operation friendlt and simple ...

VRM versus BALL MILL for CEMENT GRINDING Blaine Surface. cm2/g: 4000 Cement (OPC) Slag . Grinding systems comparison Power Consumption when grinding to 3800 cm2/gm for 150 tph capacity . Operational Guidelines ...

Trends in the performance management of cement plants JALINDIA 4 Benchmark 3 Mta Rewa cement plant in India JALINDIA Cement Association of Canada 1 Energy efficiency benchmarks Cement Association of Canada ...

OPERATIONAL EXPERIENCE FROM THE UNITED STATES' FIRST VERTICAL ROLLER MILL FOR CEMENT GRINDING By: Mark Simmons Production Manager Salt River Materials Group Phoenix Cement Plant Lee Gorby

FOR VERTICAL ROLLER MILLS by Matthias Authenrieth, Thomas Hyttrek and Andreas Reintke, Loesche , Germany, and Steven McGarel, Senior Consultant, USA ... PROCESS CONTROL INTERNATIONAL CEMENT ...

Control loop for cement mill VRM Control loop for cement mill VRM. Hi all. Can you please share with me the logic control of VRM. What factor should be included in the PID control loop? at the .

TARUN KUMAR SHEE | LinkedInSuccessfully commissioned Semi-finish cement Mass Balancing Of Cement Grinding System grinding with Roller Press and Heat and Mass balance for kiln and mill systems, false air measurement ...

WhatsApp)

WhatsApp)