WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Machinery sells rotary kiln,dryer machine,cooling machine and other building materials equipment, ball mill and other ore beneficiation as well as hammer ...

Introduction of raw mill The raw mill is a key equipment to grind the crushed materials, and the raw mill is widely used in powder-making production line including ...

The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our ...

raw mill to CF silo, 3-support kiln with. 5-stage ILC .. raw mills, two OK 33-4 vertical mills for slag .. burner fires rotary kilns with pulverised and alternative ...

May 04, 2016· re Running Raw Mill without kiln gases. Dear, Run raw without kiln hot gas is based upon your kiln stoppage time . But normaly kiln with raw mill should .

Clay-King offers solutions for artists that will take your projects to new heights. Also offers the best prices in the industry on pottery kilns.

Lawrenceburg Hometown Pizza's new "L" shaped live edge cherry bar. The long side is 22' and the other is 8'. Stop in and check it out, and have a bite to eat while ...

Clinker: reactions in the kiln. The milled and blended raw materials go to a silo and then to the kiln. Reactions which take place as the feed passes through the kiln ...

Raw Mix Preparation Raw Mix Optimization ... Raw Mill Homogenizing Silo Kiln Feed Pre-blending Optimization Module Raw Mix Optimization Module Raw Mill

Our company mainly produces the rotary kiln, tube mill, industrial kiln, vertical shaft mill ... of cement production line,rotary kiln, ball mill, raw mill ...

Manufacturing - the cement kiln. Most Portland cement is made in a rotary kiln. Basically, this is a long cylinder rotating about its axis once every minute or two.

Russian cement focus - Article - Global Cement... for a cement loading station under ... and 0 plants out of the 33 ... comprises an Atox 57.5 raw mill, a five-stage ...

The initial step in ceramic tile manufacture involves mixing the ingredients. Sometimes, water is then added and the ingredients are wet ...

Application of ESP is studied, keeping in view Indian conditions. rotary kiln and raw mill, alkali by-pass, clinker cooler, cement and coal mill, Get Price.

The cement kiln system is designed ... and the raw mix is ... and the fine product is stored in a silo of sufficient size to supply the kiln though fuel mill ...

The raw mill and preheater/precalciner use kiln exhaust gases to dry, heat emissions control technology must meet to function in the cement. Get Price

Intro: Kiln Dry Lumber at Home. Kiln drying your own wood at home can be a great way to sustainably harvest the materials around you, and dry it fast enough to build ...

Hardwood Lumber . Acadian Cypress & Hardwoods specialized in offering a complete inventory of hardwood lumber, domestic, imported & exotic. All Hardwoods are stocked ...

3.3 Raw materials for cement manufacture. The first step in the manufacture of portland cement is to combine a variety of raw ingredients so that the resulting ...

Cement Kiln Process Specialist, expert trouble shooter for process problems with cement kilns.

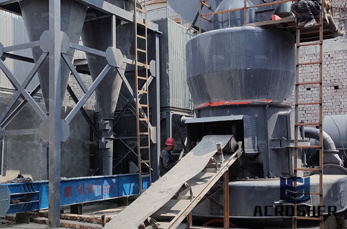

Raw Mill Introduction: Raw mill is mainly used in grinding raw materials and end products in cement plant. It is also suitable for various ores and other materials ...

Kiln drying wood at elevated temperatures also has many other secondary effects as well, such as killing powderpost beetles (a destructive wood pest) in all stages of ...

Carson's Lumbermill . Established in 1986 when we bought our first Woodmizer® Sawmill, our focus at that time was custom sawing and lumber. As our client base grew ...

Wood drying (also seasoning lumber or wood seasoning) reduces the moisture content of wood before its use. When the drying is done in a kiln, the product is known as ...

WhatsApp)

WhatsApp)