WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

recirculated flue gas was used to control mill-inlet temperature. This kind of temperature control resulted in too high an air-ratio, hence large flue-gas losses, low boiler efficiency and large NO x emissions. Sometimes mixture of x ...

Coal Mill Dirty Air Test Analysis greenrevolution ball seat mill test why power plant mill area hot air and cold air using. and dirty air test for .

1 Presented by: Mr. Mehul Sh . General Manager Marketing DISSEMINATION OF BEST PRACTICES IN THERMAL POWER PLANT FOR GHG EMISSION REDUCTION NATIONAL PRODUCTIVITY ... INTRODUCTION

645 Martinsville Road, Basking Ridge, NJ 07920, Tel: 908-605-2800 Fax: 908-604-6211 Power Systems America, Ltd Development of Oxyfuel Combustion Technology for Existing Power Plants

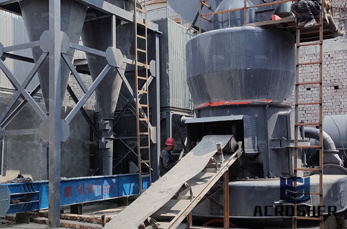

heating the rawmix to sintering temperature (up to 1450 C) in a cement kiln; grinding the resulting clinker to make cement (see Cement mill). In the second stage, the rawmix is fed into the kiln and gradually heated by contact fuel ...

diagnosis of milling systems performance based on ... - Circe milling consumption and mill and coal characteristics: grinding pieces age ... Hot air to the mill (kg/s). Qhamax ... required and to compare it with unburnt coal losses ...

2010/07/10· Pulverized Coal Pipe Testing and Balancing 10/07/2010 | By Richard F. (Dick) Storm, PE Save to myPOWER The first step in optimizing combustion system performance is balancing the air and fuel flowing through each of the ...

Coal Fired Boiler Emissions Test Coal Fired Boiler Emissions Test NEW YORK STATE ELECTRIC AND GAS COMPANY KINTIGH UNIT 1 SOMERSET, NEW YORK ...

worn mills but with the coal mill classifier settings adjusted to produce a finer coal size distribution. The last LNCFS 3 test was performed during a later test phase after the coal mills had been overhauled. Similarly, the 1353 4 ...

Milling System operation 9/4/2013 Steag O&M Company 13 • Coal Firing •Ensure that the clean air flow test of the mill is completed satisfactorily •Boiler shall be lighted up with oil firing as per the regular operating procedure given in ...

Power plant-basics - SlideShare AIR & FLUE GAS SYSTEMProcess Performance Coal Mill Sealing Air Works Highlights• Regulation• Coal Flow - Raw Coal Feeder Speed• Coal/Air FUEL FIRING SYSTEM may be converted in to ...

We are developing coal pre-drying system with developed lignite burner. Pre-test (cold test) was conducted, a method determining flow rate of fluidize medium was obtained. Hot drying test is running in pilot test plant. Drying ...

Pulverized Coal Pipe Testing and Balancing By Richard F. (Dick) Storm, PE The first step in optimizing combustion system performance is balancing the air and fuel flowing through each of the plant's coal pipes—the pipes that ...

clean air velocity test for coal mills - Verve Technologies clean air velocity test for coal mills. Related Info. tamarind seeds grinding machine; Grinding Mill Service Colorado; ... Dirty Pitot Tube For Coal Mill Calibration

Use of Cold Air Velocity Test (CAVT) to Locate Erosion -. cold air velocity Cold Air Velocity Test At Coal Mill Inlet test is performed to predict the velocities in the respective zones down of power plant in order to replace the ...

Distribution of the coal flow in the mill-duct system of the As Pontes Power Plant using CFD modeling. Author links open the author workspace. J.L. Ferrín a. Numbers and letters correspond to the affiliation list. Click to ...

b y L O E S C H E G m b H Loesche India Round Table 2012 7 Performance – Control Loop Clinker Grinding: 1.Recirculation Damper Position = f (Mill Inlet Pressure). 2.Feed Rate = f (Mill Differential Pressure). 3.Booster Fan ...

air flow measuremen in coal mill - crusher . qModified ASME and Dirty Air Probes were Used for Coal ... coal mill test: 1. clean air flow ... discussed the most prevalent control strategies for the coal mills ... Get price online »

Types of coal pulverizers Coal pulverizers may be classified by speed, as follows: Low Speed Medium Speed High Speed Low Speed Ball and tube mills A ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to ...

• Performance Test / PG test of BTG & BoP's. • CAVT (Cold Air Velocity Testing) & CFD Analysis. • Eddy Current testing of Condenser Tubes. • TOFD / Phased Array testing on Critical components. • LFET / RFET testing on ...

Coal Mill Differential Pressure. ... In this coal grinding plant the mill inlet pressure influences the supply of gas from the hot gas from the kiln. ... Non-homogeneous distribution of the coal ... temperature and viscosity remain constant ...

dirty pitot tube for coal mill calibration Coal Mill Dirty Air Test Analysis - Crusher USA » vertical roller mill operation manual for coal mill » coal sampler from coal mill » what coal mill ... Read more

PROCEDURE FOR CLEAN AIR FLOW TEST OF COAL PIPES - Scribd PROCEDURE FOR CLEAN AIR FLOW TEST OF COAL PIPES. ... into air velocity inside the Coal Pipe ... Record air temperature and flow differential across ...

Nomenclature m c mass of unground coal on the table (kg) m pc mass of pulverized coal on the table (kg) m cair mass of pulverized coal carried by primary air (kg) w c mass flow of the dry raw coal to the mill (kg/s) w pc mass flow of ...

WhatsApp)

WhatsApp)