WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

gold processing: preparation of the ore for use in various products.

International Journal of Scientific and Research Publications, Volume 3, Issue 5, May 2013 2 ISSN 2250-3153 ratio, ball size and grinding time ...

Use of Iron Ore Pellets in Blast Furnace Burden Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size less than 200 ...

The crowd cheered in California on Monday, when Apple announced HomePod, a new smart speaker armed with Siri, the company's virtual assistant. Minutes later, an ...

CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Minerals Process Technology Asia-Pacific, Brisbane, Australia e-mail: alex.jankovic@

Froth flotation is considered to be the most widely used method for ore beneficiation. In ore beneficiation, flotation is a process in which valuable minerals are ...

TECHNICAL REPORTS SERIES No 314 Guidebook on Design, Construction and Operation of Pilot Plants for Uranium Ore Processing itWivs 'z NTERNATIONAL ATOMIC ENERGY AGENCY ...

Minnesota's iron ore was actually discovered while prospectors were searching for gold. Since the object of their search was gold, the iron was ignored.

1 1 Froth Flotation – Fundamental Principles Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of ...

1.2. Chalcopyrite Ore Production The sulfide ore minerals including chalcopyrite (CuFeS 2), sphalerite (ZnS), galena (PbS) provide the major sources of the world's ...

Thousands of years ago, indigenous people living in the California Channel Islands relied on a manufacturing process that exposed them to dangerous chemicals that ...

Job Interview Practice Test Why Do You Want This Job? Answer this job interview question to determine if you are prepared for a successful job interview

THE BASIC PROCESSES OF GOLD RECOVERY INTRODUCTION. Man has held a fascination with recovering and acquiring gold almost since the beginning of time.

Iron ore pellets and Pelletizing processes. Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size less than 200 mesh ...

Aluminum is manufactured in two phases: the Bayer process of refining the bauxite ore to obtain aluminum oxide, and the Hall-Heroult process of ...

Drying and Primary Grinding. The essential additives quartz, sand and iron ore are added to the homogenised material and this mixture is then ground to a powder with ...

Slag is the glass-like by-product left over after a desired metal has been separated (i.e., smelted) from its raw ore. Slag is usually a mixture of metal oxides and ...

Gold cyanidation (also known as the cyanide process or the MacArthur-Forrest process) is a hydrometallurgical technique for extracting gold from low-grade ore by ...

Highlights Zinc oxide is an extremely versatile industrial chemical. There have been significant changes recently in the ZnO industry. Here we review the ...

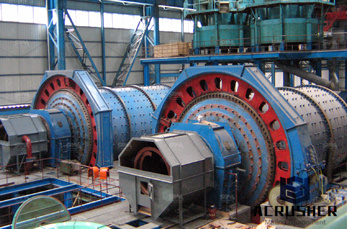

Figure 1 : Grinding Power to produce various product sizes in a Ball Mill (9mm balls) and an Isa Mill (2 mm sand) (for KCGM pyrite concentrate)

Located near Salt Lake City, Ut, US, Bingham Canyon celebrated its 100th anniversary in June 2003. The Bingham Canyon mine, Copperton concentrator and .

The process of extracting copper from copper ore varies according to the type of ore and the desired purity of the final product. Each process ...

The first commercially successful decaffeination process was invented by the German coffee merchant Ludwig Roselius in 1903 and patented in 1906.

Types of Chemical Weathering: Dissolution. H 2 O + CO 2 + CaCO 3 --> Ca +2 + 2HCO 3-water + carbon dioxide + calcite dissolve into calcium ion and bicarbonate ion

WhatsApp)

WhatsApp)